Description

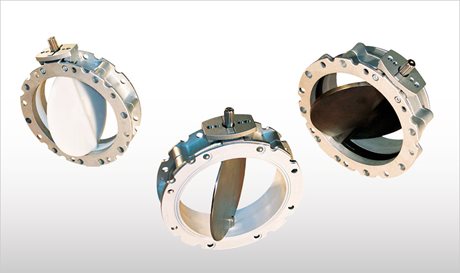

VFS Butterfly Valves consist of two high-pressure aluminium alloy die-cast semi-bodies, a SINT polymer composite or cast iron swivel disc, and a pre-stressed elastomer seal.

For the food industry a version with stainless steel disc and an FDA/EN-approved, integral seal is available.

While V1FS has a top flange and beaded bottom section – suitable for the attachment of a flexible sleeve – V2FS comes with identical top and bottom flange.

Function

To close silos, hoppers or bins containing powders or granules, VFS Butterfly Valves range among the most widely used equipment worldwide.

What used to be custom-built items for specific applications, WAM has turned into a mass-produced, industrial product with features that allow extremely versatile use.

VFS Butterfly Valves are used in all types of powder and granular material processing plants where interception of gravity-fed or pneumatically conveyed dry materials is required. They are fitted beneath hoppers, bins, silos, screw or other type conveyors, or to intercept pneumatic conveying ducts. Due to their special design and engineering materials used, they represent a particularly cost-effective yet most efficient solution.

Features

- V1FS with top flange and beaded bottom section suitable for fixing a flexible sleeve

- V2FS with identical top and bottom flange

- Dust tight and pressure-proof up to 0.2 bar (2.9 PSI)

- High-pressure, aluminium alloy die-cast semi-bodies

- Disc in cast iron, SINT engineering polymer, or stainless steel

- Seals for standard or food-grade applications

- Made up of few components

- Used for powders, granules, pellets

- Lightweight and easy to handle

Benefits

- Highly abrasion-resistant

- Easy to fit

- Time-saving maintenance

- Low operating and maintenance costs

- Interchangeable discs

- Ex-stock delivery

Options

- ATEX

–certified - Compliant with EN 1935/2004 standards

- Food-grade version with stainless steel disc and integral seal