Description

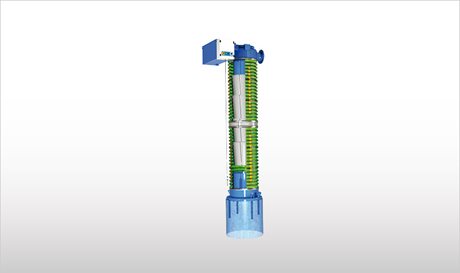

ZX Loading Bellows are used for efficient, dust controlled discharging of dry, dusty bulk solids into ships, barges, or stockpiles. This type of loading spout is provided with inner tapered cones to contain the flow of material and an outer bellows to provide for dust removal.

Function

First the Loading Bellows is lowered from stand-by position towards the ship hold or stockpile. As soon as the bellows outlet touches the ground, a slack cable switch mounted outside the transmission box stops lowering of the bellows. The limit switch inside the transmission box stops both full extension and contraction of the bellows. Material loading starts by opening the silo outlet valve.

Once the bellows is fully contracted, the cable limit switch inside the transmission box stops operation.

Features

- Inlet diameter: 500 mm (19.6 in)

- Maximum throughput rate: 850 m3/h (500 cfm)

- Operating temperature: -40 ~ 150 °C (-40 ~ 300 °F)

Benefits

- Excellent dust-free loading due to special bottom skirt design

- Two lifting cables outside material flow raising and lowering the loading bellows without cable wear by material friction and obstruction to material flow

- Two level indicators outside material flow

Options

- ATEX version

- Single bellows, double bellows or single bellows with internal steel cones

- Various bellows and fabrication materials available according to material handled

- Control panel with remote control

- Available with different types of level indicators

- Outlet vibrator

- Motor-driven winch